ROUTE OPTIMIZATION

ISSUE

For transport companies, route optimisation is a major challenge. And Transarc is not one to deny it! This transport specialist has long wondered how to effectively improve the organisation of its routes. Indeed, for each route, Transarc records several kilometres of empty transport from point A to point B, known as overland journeys. The coach is running but not transporting anyone, which is a pity. Therefore, Transarc contacted Neovision to find a solution.

SOLUTION PROVIDED

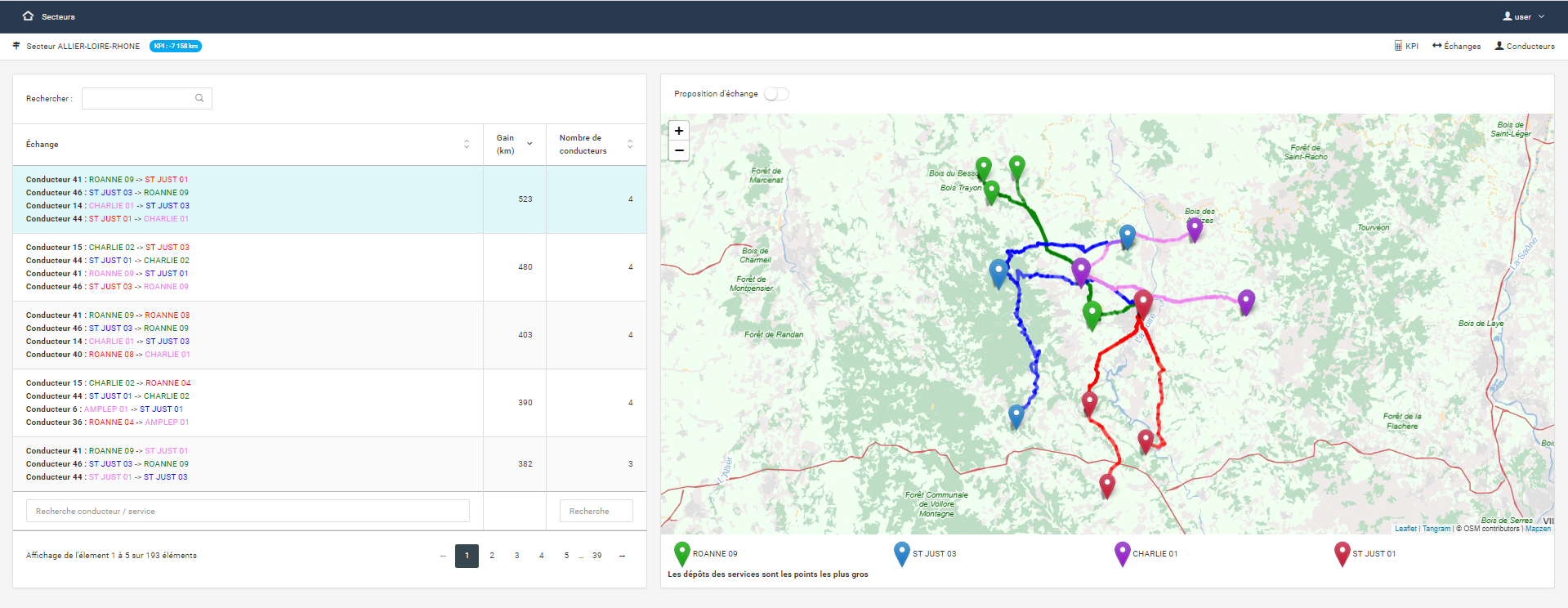

To meet this challenge, Neovision developed a web application for Transarc to optimise empty runs, called Factor K for Kilometres. By exchanging certain routes/assignments, Transarc optimises its routes and reduces the distances of overland journeys.

CUSTOMER BENEFIT

Thanks to the artificial intelligence used in the Facteur K software, Transarc was able to make a profit of 200,000 kilometres, or €200,000, in one year on empty runs. By adjusting the routes and swapping some of them between drivers, Transarc obtained an ROI of 3 months. In addition to the financial aspect, there was also an environmental factor with less CO2 emissions, and a social factor with drivers spending less time alone in their bus.

REALIZATION

Transarc is a road transportation company, more specifically a coach company. It has over 700 vehicles and 16 depots in the regions of Grand-Est, Bourgogne-Franche-Comté and Auvergne Rhône-Alpes.

The empty round trips represent a real constraint but also a significant expense.

As good mathematicians that we are, let’s take five minutes to look at the problem… Thanks to Transarc, we know that 1km travelled by a coach is equivalent to a €1 charge for Transarc (salary, fuel, taxes, wear and tear, etc.). Patrick, a coach driver at Transarc, does 10km of HLP travel before arriving on his first round, then he goes on to his second round which is at the other end of town (say 6.54km). He then moves on to three more rounds, all equally far apart (1.2km, 7km and 2.6km). As the sun sets, he drops off his last passenger and rides 14km back to his depot. All in all, Patrick will have travelled more than 41km in one day in HLP, which represents a €41 charge for Transarc.

So if we do the following calculation:

n empty km X x drivers X y days = a very expensive bill and an unhealthy planet!

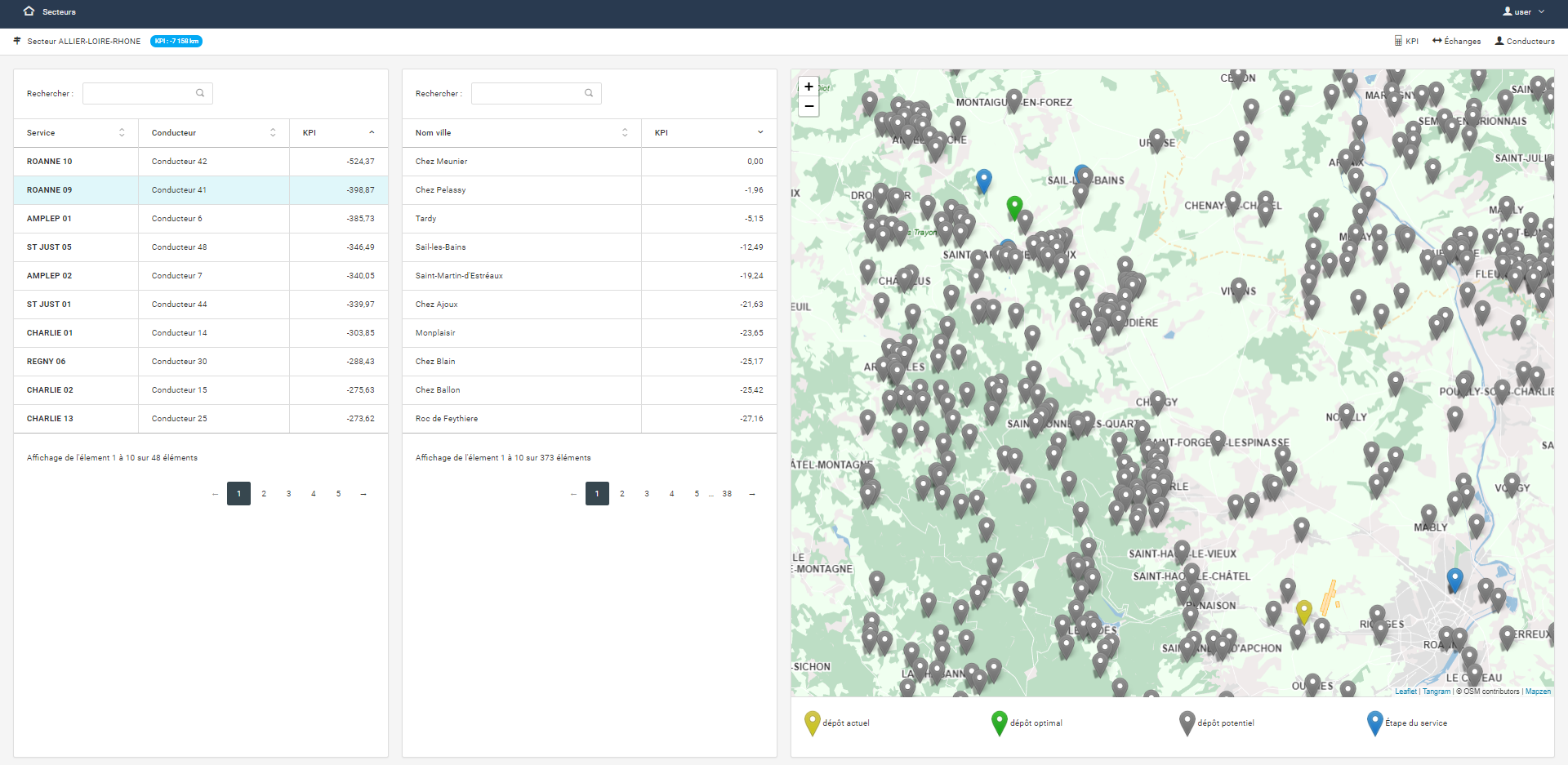

They have therefore named the indicator for calculating this cost the k-factor. It is the result of the difference between the optimal HLP needed to complete the rounds with the best depot and the actual HLP. But how do we get the optimal? Well, by changing the depot location!

In order to best meet Transarc’s needs, Neovision first challenged its client’s idea. Initially, the company wanted to calculate the optimal depot locations to know where to recruit. However, upon further analysis, Neovision noticed that it was possible to go further by optimising Transarc’s operations, with the available resources, while recommending the right recruitment areas. Double shot!

To launch this project, Neovision first carried out a pre-study. This was followed by a study and software development phase. In 6 months, Transarc was able to integrate a functional AI solution allowing it to optimise its empty runs. Since then, Neovision has been providing level 2 maintenance for the software to ensure that the service is always at its best. Level 1 maintenance is provided by Transarc’s IT department trained by Neovision.

Neovision’s goal was to minimise the k-factor in order to ensure a better performance for Transarc. Neovision relied on OpenStreetMap, an open source mapping database that allows for the collection of geolocated data (via GPS, for example), and on part of its ecosystem of third-party software. Thanks to the latter, Neovision has created an algorithm capable of calculating the k-factor by playing with the geographical positions of the depots and those of the various routes. The purpose is to exchange routes between drivers from different depots to obtain the best one.

To make the use of this tool more ergonomic for Transarc, Neovision then developed a web application called Facteur K. It allows the user to visualise potential depots on a map, thanks to a coloured layout, or to simulate the exchange of routes between drivers that you would like to make.

After two months, Transarc, having made the tool its own, realised that the map display also allowed it to carry out an optimisation that it had not thought of: moving the depots of certain drivers.

A few months later, in April 2019, Transarc and Neovision were featured in a report by TF1. The report praised the merits of the Facteur K software and another project – in progress, at the time – explaining the benefits and advantages of investing in artificial intelligence even when you are an SME.

Patrick wastes less time on journeys without passengers, less money on wasted fuel, and Mother Nature thanks him.

TECHNOLOGIES & ASSOCIATED EXPERTISES

OPERATIONS RESEARCH, OPEN DATA, DJANGO, LEAFLET

TÉMOIGNAGE

« We were delighted to work with the NEOVISION team on this highly innovative project in the transportation field. The specifications were respected and the final result goes beyond our initial expectations. If we had to underline the strong points of the team I would say they are the following:

- Very deep understanding of the problem and our expectations

- Ability to provide ergonomic and functional deliverables

- Respect of deadlines

New projects are waiting for us and I can’t wait to start up! »

Damien Rameau, Manager at Transarc

Date

9 June 2022

Category

Applications Web, Cloud, Environnement, Recherche opérationnelle, Transport